Case study: automating immune monitoring with IRIS 2

Published: October 28, 2025

Updated: November 17, 2025

5 minute read

Authored by: Berend Bassleer

How Mabtech IRIS 2 became the final step in a fully automated workflow

Researchers at the Vaccine Research Center (VRC), NIH, set out to automate immune monitoring at scale, the first end-to-end automation of its kind. Doing so, they faced familiar challenges: how to preserve the precision of single-cell resolution in FluoroSpot analysis while scaling to dozen of plates per run.

The results of their efforts, published in Methods as "HI-CeFSpot: High-throughput Immune Cell FluoroSpot assay", not only sets a new benchmark for throughput, but also highlights the pivotal role of Mabtech IRIS 2 in building a truly end-to-end automated system.

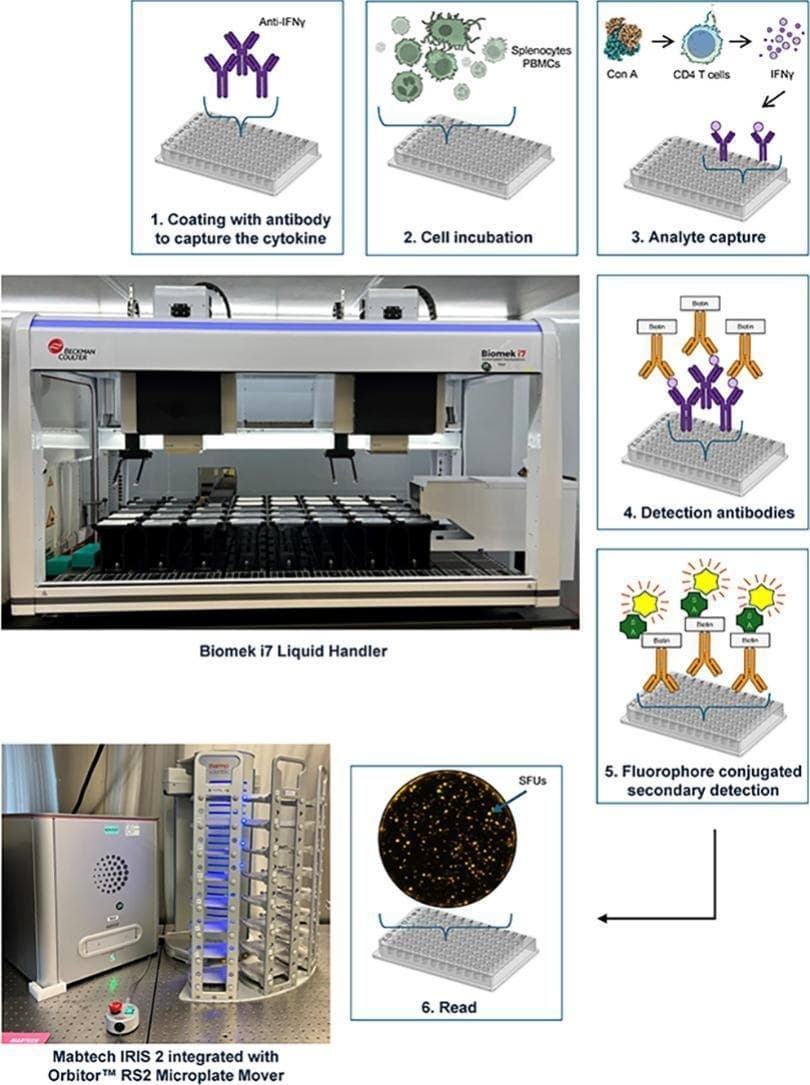

From manual steps to a fully automated pipeline

Traditionally, ELISpot and FluoroSpot assays rely on highly skilled personnel. Apart from variables introduced during the pre-analytical steps, such as sample handling, other factors like pipetting steps, incubation timing, and plate washing introduce variability that can affect assay reproducibility. To address such variables, the VRC team developed a High-throughput Immune Cell FluoroSpot (HI-CeFSpot) assay: a fully automated FluoroSpot workflow combining Beckman Coulter's Biomek i7 liquid handler, Thermo Fisher's Orbitor robotic arm, and Mabtech's IRIS 2 reader.

The result is a system capable of processing up to 25 plates per run, from plate blocking to readout.

Why IRIS 2 is a perfect match for automation solutions

IRIS 2 is uniquely suited for robotic integration: with its fixed-focus optical design, self-calibrating XY-table, and LED-based excitation system, it ensures consistent imaging across plates – the perfect companion for high-throughput setups. On top of this, with our supplied Performance Qualification (PQ) plate, IRIS 2 can be validated to meet clinical testing expectations and regulatory compliance.

In the HI-CeFSpot workflow, IRIS 2 gets plates inserted directly from Thermo Fisher's Orbitor RS2 robotic arm. This integration of IRIS 2 through the Momentum software enables automated plate loading, reading, and data export. Once a plate is read, the robotic arm returns it to the same location in the hotel and queues the next plate to be loaded. With this integrated setup, traceability is maintained and operator variation is eliminated.

Not only is IRIS 2 uniquely positioned for unprecedented automation implementation, but the Apex software allows for post-acquisition optimization without needing to re-read the plates. Aesthetic parameters such as brightness and contrast as well as parameters that adjust spot counts like size and intensity, are easily adjusted by users after the readout. This is only possible on Mabtech's reader systems since it is the only platform that records the full, uncompressed signal from each spot. In essence, this means flexibility and time savings without compromising data quality, especially for large screening campaigns.

Precision, reproducibility, and speed

In the presented study, the team achieved an incredible intra-plate and inter-plate precision below 10% and an intra-assay variation below 15%, even across multi-plate runs. To develop this assay, immune cells from non-human primates (NHPs) were screened against various stimuli to test the release of interferon gamma (IFN-γ) on our FluoroSpot Plus: Monkey IFN‑γ (550) and FluoroSpot Plus: Monkey IFN‑γ/TNF‑α/IL‑2 kits.

The entire pipeline demonstrated:

- High reproducibility across 50 plates

- No detectable cross-contamination between runs

- Accurate quantification of peptide-specific immune responses in NHPs

- Suitable throughput for clinical trial endpoint testing

The entire process, from cell plating to final readout, could be completed within three days, with IRIS 2 providing the final analytical step.

Enabling large-scale immune monitoring

By automating the entire FluoroSpot workflow, researchers can now run large vaccine or immunotherapy studies with minimal hands-on time and increased reproducibility. By integrating IRIS 2 in the HI-CeFSpot workflow, it opens the door for:

- Multiplexed readouts, using up to four fluorescence channels per plate

- Scalable screening, adaptable to new analytes or cell types

- Increased flexibility for data analysis, easily change parameters after readout

For labs seeking to move towards large-scale immune profiling, this study provides an excellent blueprint on how to get started and demonstrates how Mabtech can be your partner in your automation efforts for ELISpot and FluoroSpot.

Looking ahead

Automation is not only about speed, it is also about confidence in the results. The ability to deliver consistent, high-quality FluoroSpot data at scale allows institutions to focus on biology rather than manual variability.

As more and more labs are looking to expand throughput and standardize immune monitoring, the integration of IRIS 2 with robotic platforms like Thermo Fisher's Momentum and Orbitor RS 2 alongside cell- and liquid handling setups such as Biomek i7, represents a major step towards a complete hands-free, high-throughput immune analysis platform.

As always, Mabtech is here to help you with every step of the way, however your automation process might look like. Feel free to contact us to see how IRIS 2 can benefit your automation efforts.

Reference: Jethmalani Y. et al. (2025). HI-CeFSpot: High-throughput Immune Cell FluoroSpot assay. Methods 244, 210-218. https://doi.org/10.1016/j.ymeth.2025.10.002